Offline Robot Programming

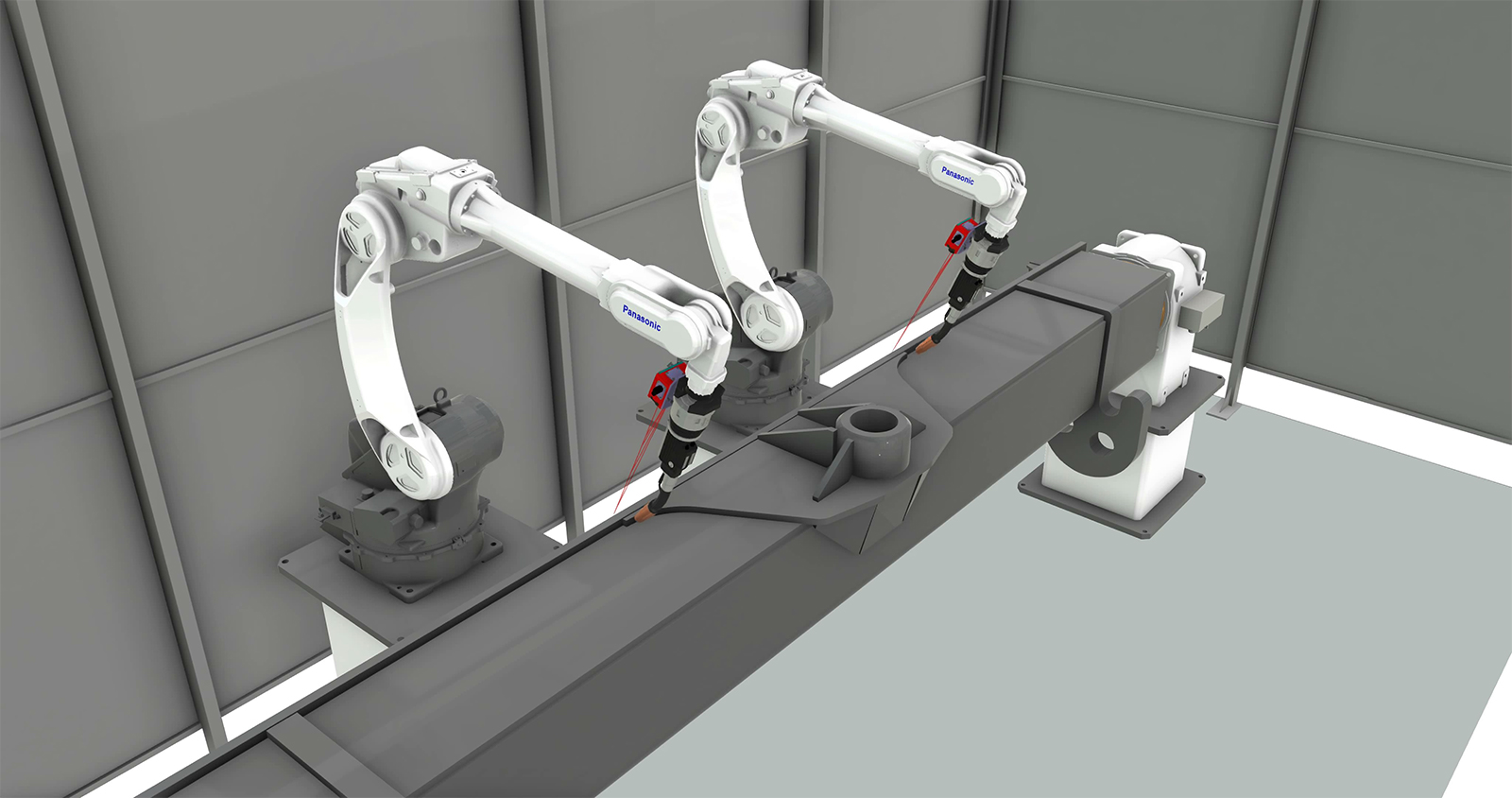

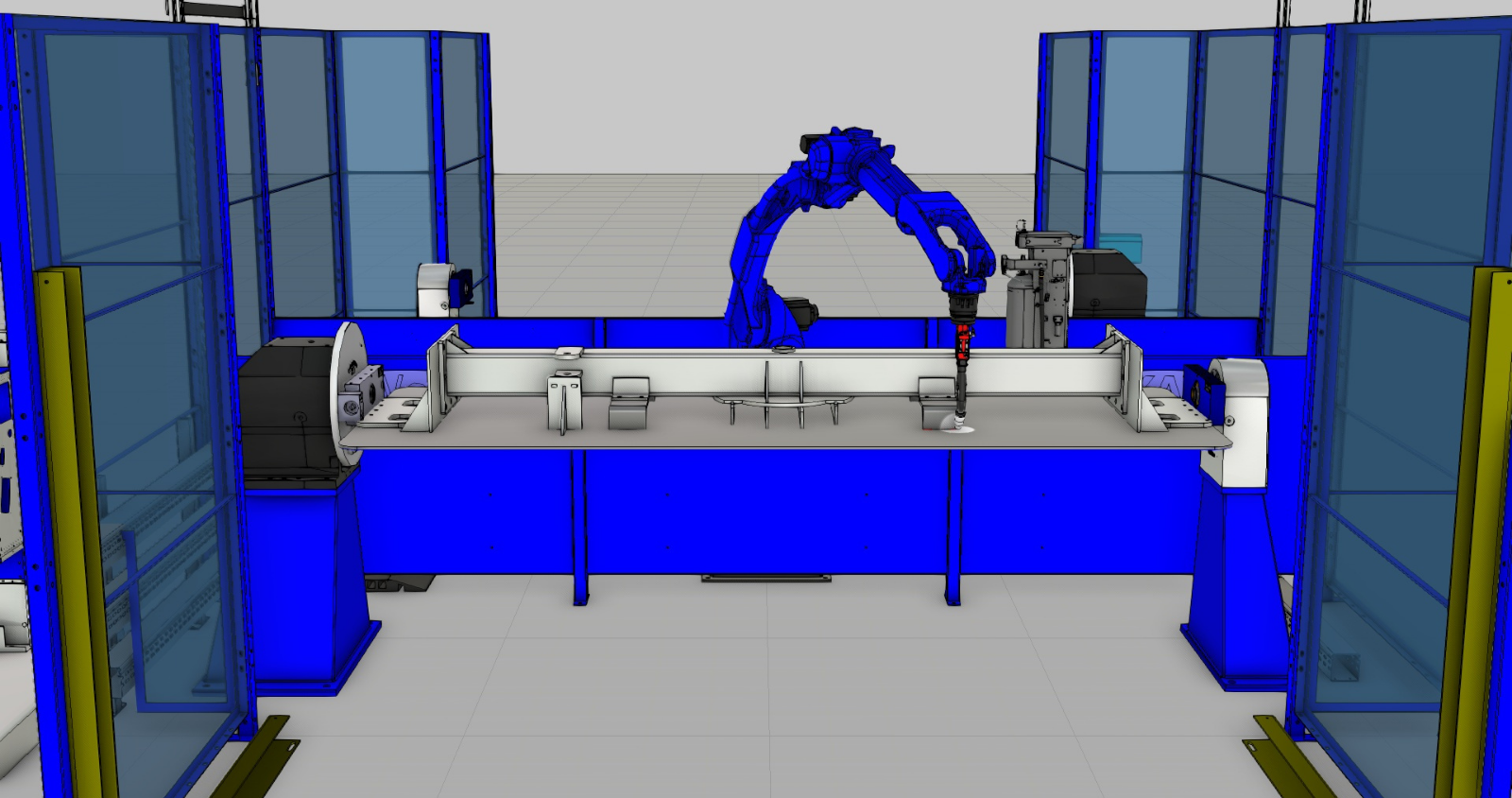

Creates Autonomous, Intuitive Weld Paths

It’s becoming more common for welding robots to perform set tasks for only a short time before needing to be reprogrammed, particularly in SME environments. Traditional methods of reprogramming robot welding tasks require the robots to be taken out of production for long periods, greatly affecting productivity and the bottom line.

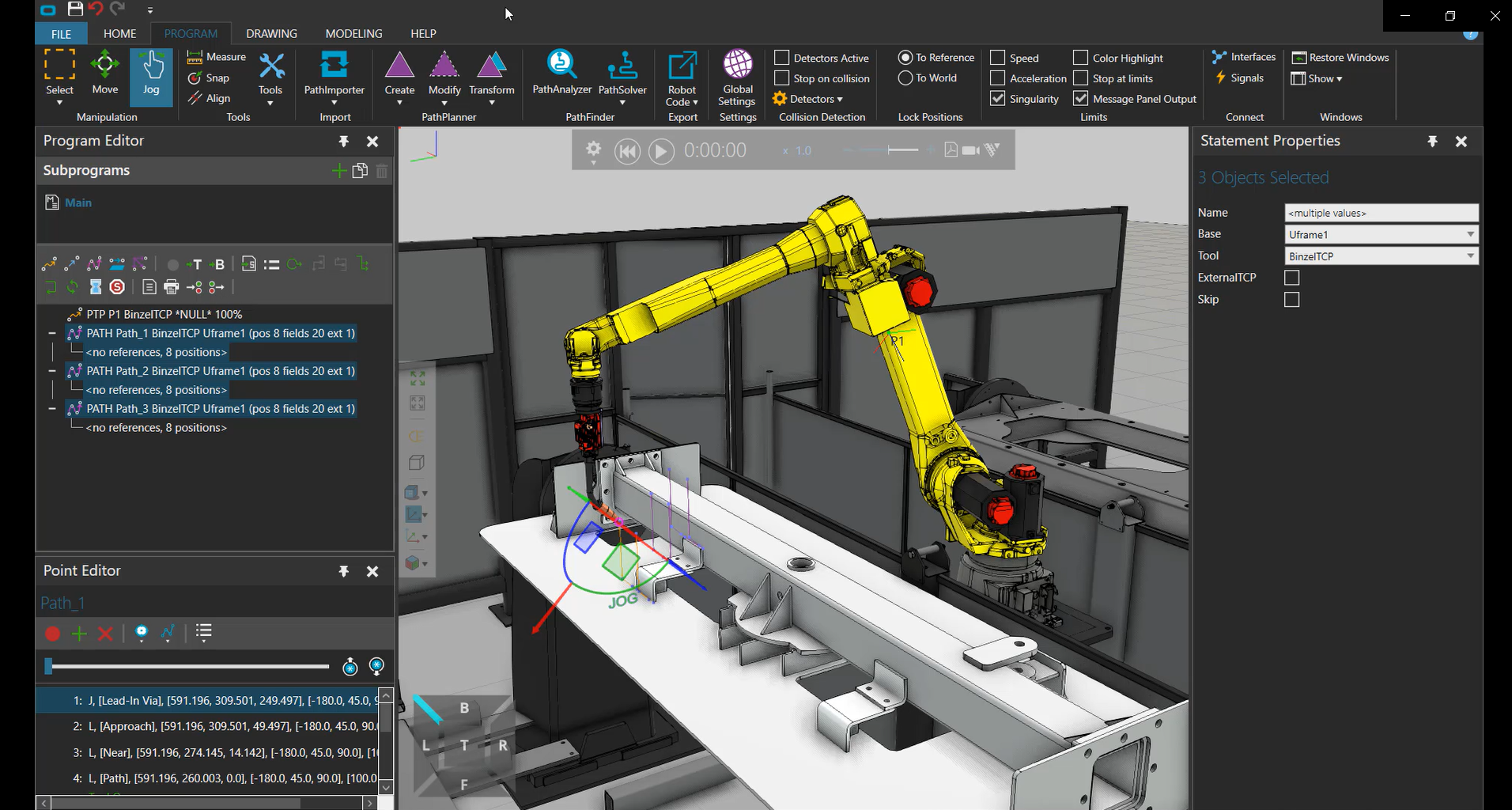

OCTOPUZ Welding Features:

- Implement a variety of welding strategies such as multi-layer, stitch, weave, seam tracking, touch sensing, and more

- Utilize multiple touches per path or global touch correction (6-dimensional)

- Fully simulate touch-sensing, multi-layer, stitch, and weave

- Parametric and reusable weld creation

- Simultaneously calculate up to three external linear axes