Create responsive and flexible

machining paths for complex shapes

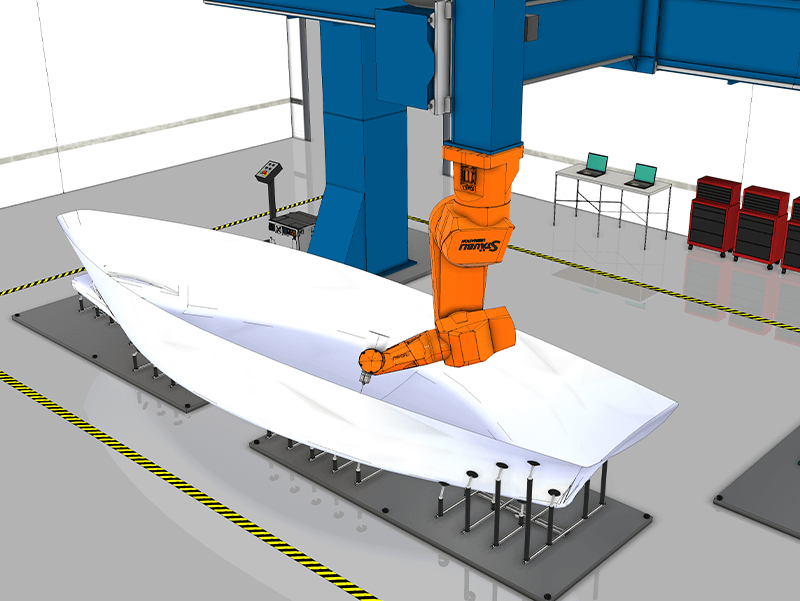

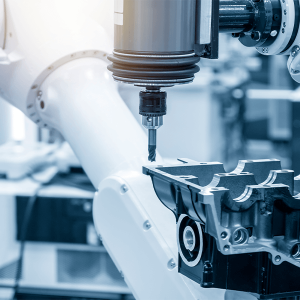

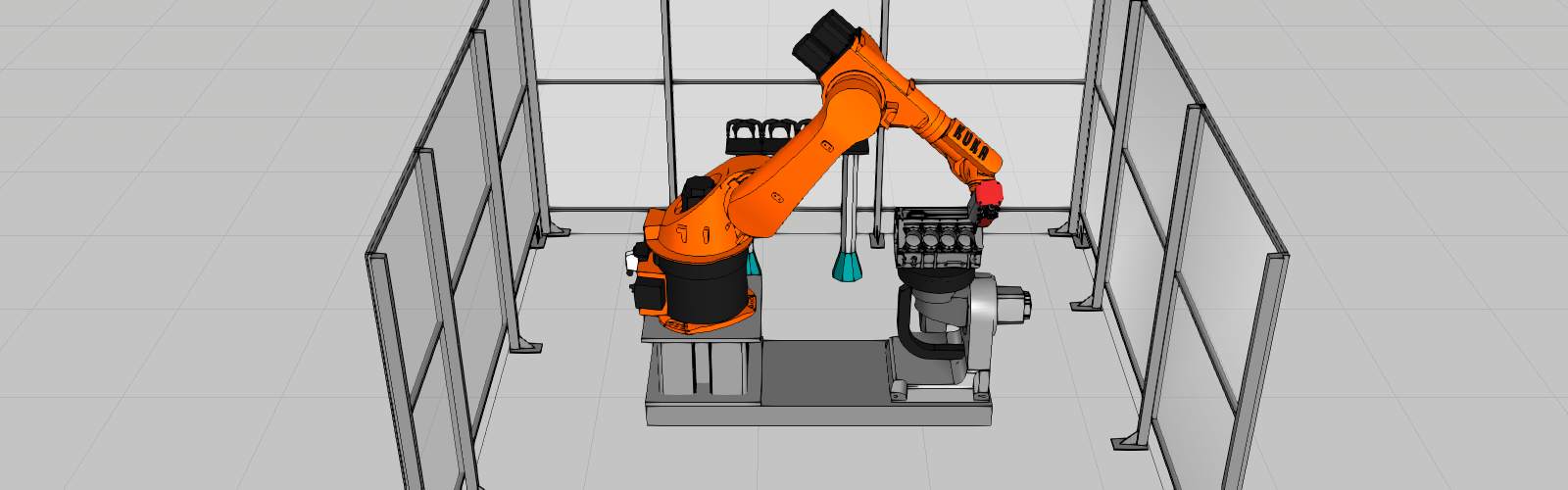

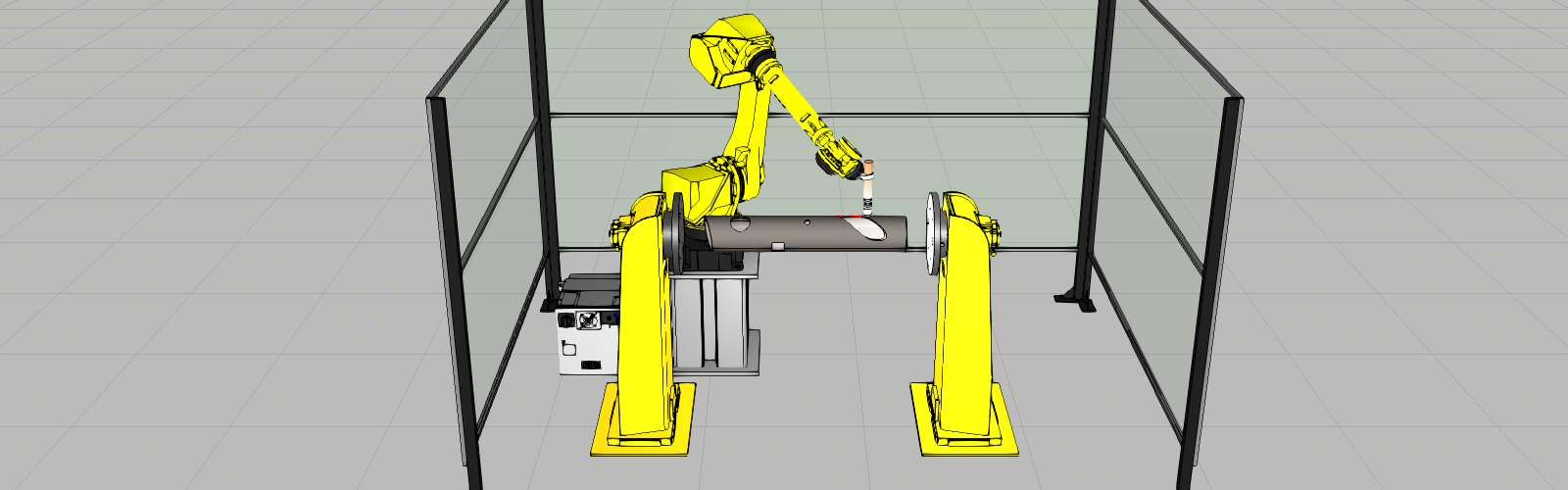

There is a growing requirement for more complex shapes to be created in the manufacturing process, many of which are not viable for traditional machine tools. 6 or 7-axis robots are ideal for carrying out machining work because they can accommodate size requirements and complex movements.

Programming machining paths with OCTOPUZ ensures a high level of accuracy and rigidity so you can increase your manufacturing capabilities.

OCTOPUZ Machining Features:

- Configure multiple angle settings

- Set constant steps across surface

- Create remote tool center points for carrying parts to stationary tooling

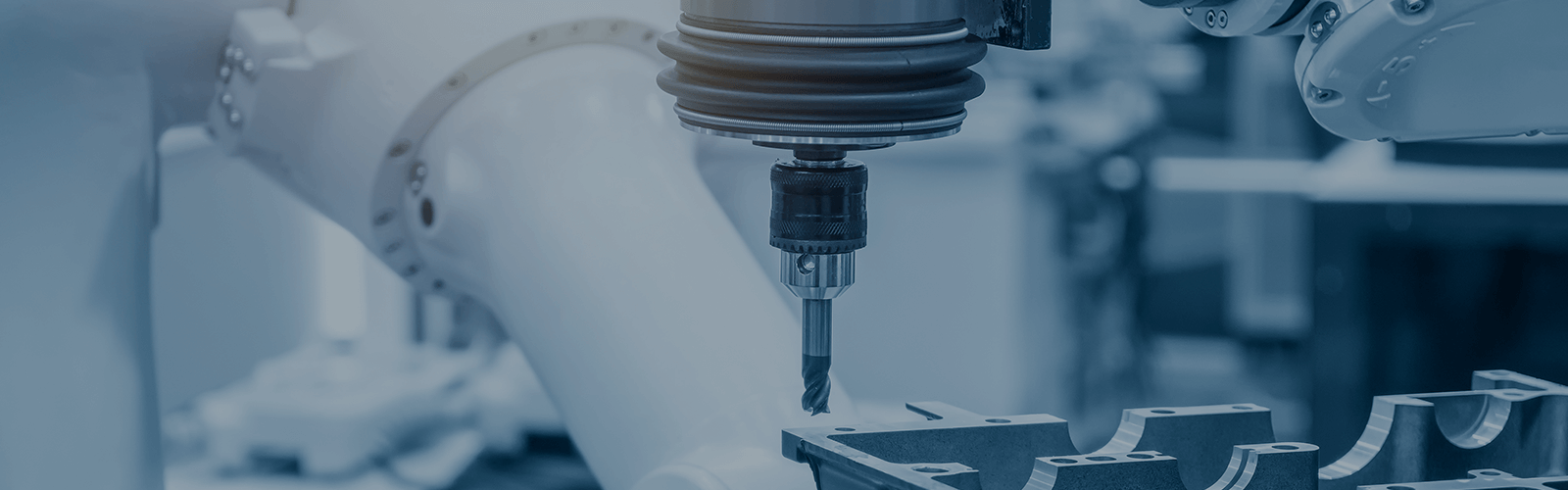

- Utilize high-speed toolpaths to increase accuracy and speed

- Integrate roughing and finishing operations

- Simulate the full process including changing tooling or entire heads

- Easily generate complex drilling paths

- NC Import and Tool Manager